Hand trolleys are essential tools for blue collar workers. Nowadays, most trolleys are made in China. Chiu Kee is one of Hong Kong’s last hand trolley maker. Marked with green paint and the label “Chiu Kee”, the local trolleys are hand-made from “angle iron” frames. Yet, Chiu Kee plans to end its business before Lunar New Year, marking the end to another made in Hong Kong story.

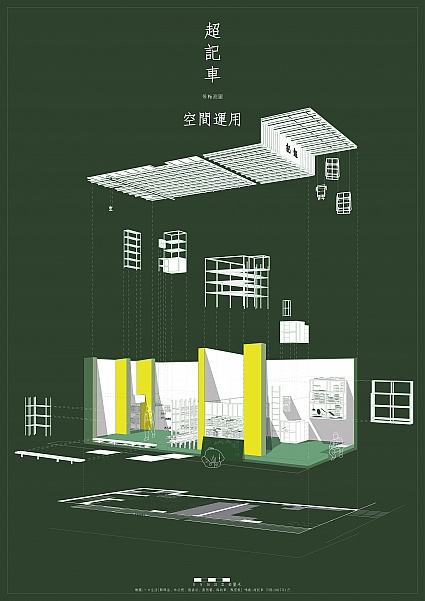

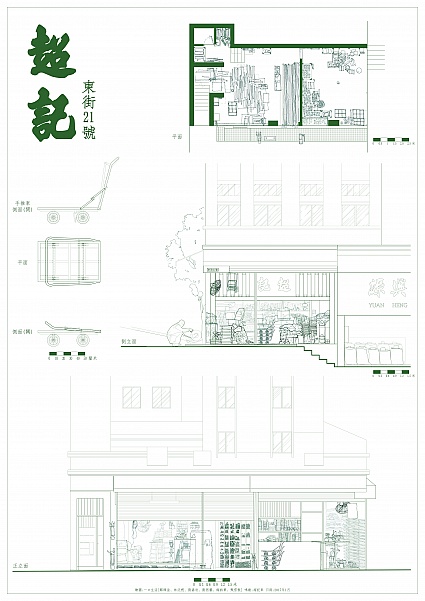

Located between Upper Lascar Row and East Street, the owner of Chiu Kee is a middle-aged man in dark blue uniform and a diamond earring. Now in his 50s, Mackey “Four Eyes” Li has worked in the industry for 31 years, and is one of the few remaining trolley artisans in Hong Kong.

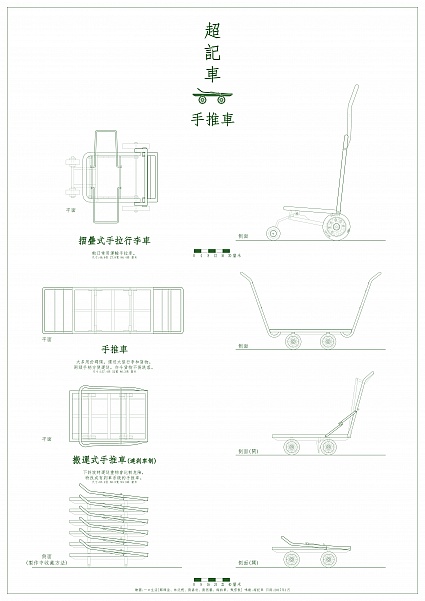

The story of iron trolleys begins with Mackey’s father Yuen Chiu Li (Chiu Kee). In the old days, Chiu Kee made a living by mending buckets and tools with his soldering tools. Later on, Chiu Kee became a blacksmith, making things such as bed frames and metal buckets. Back then, pier workers transported goods either with their bare hands or by wooden trolleys. Chiu Kee improved on the design and made iron trolleys that could carry a heavier load and were more durable. Yet, workers and shops were slow to adapt to the new design. Over time, Chiu Kee accumulated more orders by word of mouth. He also improved on the original design by adding handbrakes.

Mackey Li is the fifth youngest amongst his brothers and sisters. Knowing that the trolley business is tough but profitable, Mackey’s father intended to pass his business to other relatives. However, Chiu Kee and his relatives had a row, which put an end to their venture. Four Eyes joined the business at 18 years-old, and has carried the torch for the last 31 years.

Four Eyes’ first trolley was made after his father passed away. Initially, Chiu Kee intended Four Eyes to be in charge of operation, and left the trolley making to his workers. One of the workers soon retired, and the other was injured. With his father gone, Four Eyes had no choice but to carry the load. The challenge spurred Four Eyes’ growth. In his peak, Four Eyes could make twenty trolleys within three days.

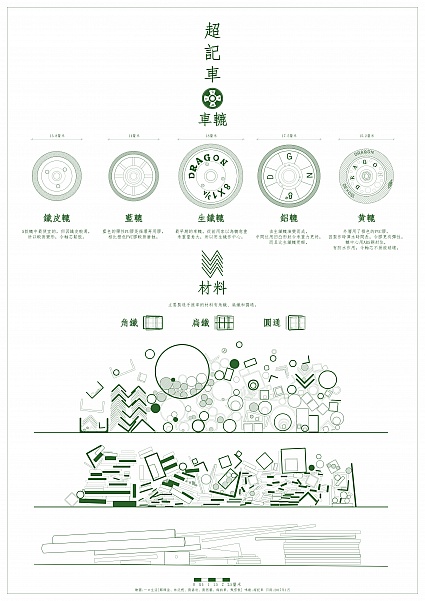

Nowadays, most trolleys are made in China. Some say that they break easily after a year and a half. Chiu Kee’s hand-made trolleys, on the other hand, could last at least five years. Apart from the use of high quality “angle iron”, the trolleys also come with a friendly design. Before every new order, Four Eyes inquire his buyers of their intended use, adjusting his design to suit their need. “If the trolleys are used for carrying liquid, I make adjustments in the axes so that they won’t topple over,” he explains.

After half a century, Chiu Kee’s trolleys have evolved in Four Eyes’ hands. Small adjustments are made to improve their durability. The trolleys are 50% lighter but retain the same load amount. Occasionally, Four Eyes would ask factories to custom-make wheels for his trolleys.

With its durability, Chiu Kee’s trolleys depart from the business strategy known as “planned obsolescence”. Although this affects his sales number, Four Eyes has learned to embrace new opportunities. For instance, the antique stores on Upper Lascar Row asked him to custom-make metal stands for their antiques. Other orders such as outdoor chairs for chain coffee shops also helped sustain his business.

Throughout the years, Four Eyes have also embraced challenges. For instance, a highbrow fashion brand once asked him to help weld an art installation. “They gave me a few hundred metal rods, asking me to convey a feeling of ‘a brooding storm’”. Four Eyes thus welded the metal rods into the shape of a hurricane. The installation was exhibited in the Landmark, which gave him a sense of satisfaction. In his spare time, Four Eyes have also participated in the Red Bull Soapbox Race and Flugtag, earning a few accolades.

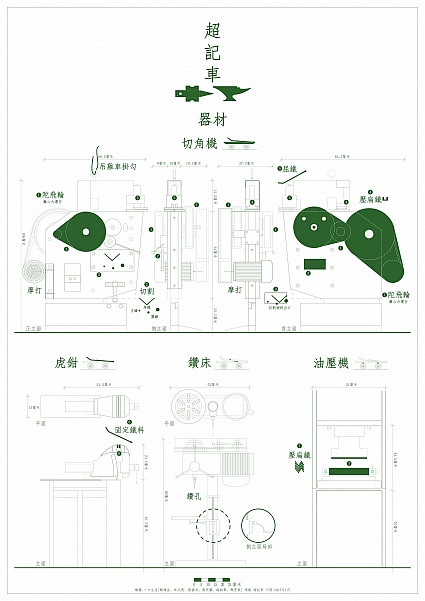

Four Eyes plans to end his business before Lunar New Year of 2017. With its closure, there is one less local handcraft. Four Eyes plans to donate his small-scale machines to “Wheel Thing Makers”, a local group that focuses on designing bicycle parts for the community. As for his craft and experience, Four Eyes has yet to pass them on, “Most people are satisfied with one finished product. But they are not willing to learn the basics of using a hammer. Without the basics, their products aren’t up to standard.”

After thirty-one years pushcart making, Mackey “Four Eyes” Li holds onto quality with the heart of a stubborn artisan.

Letting go of his pushcarts, Four Eyes mulls the next stage of his life.